The concept of a 1,000-horsepower street engine has been around for more than a decade; yet, the definition is just now coming into a clearer focus for performance enthusiasts. Boost and E85 used to be the only pathways to such power numbers in a boulevard cruiser. These days, displacement, cylinder head development and valvetrain advancements have paved the way for a naturally aspirated big-block that not only delivers 1,000-plus horsepower to the flywheel but also runs on 91-octane fuel. Meet the 632ci GM-compatible big block from BluePrint Engines.

BluePrint designed the iron cylinder block and has it cast in Germany, then machined in the company’s Nebraska shop. The engine is one of the first to feature the new F-series bearing from Clevite.

This new package is a bold leap forward from the original 815-horsepower 632ci big-block that BluePrint developed some 10 years ago. That offering has been one of the most popular performance engines in the company’s lineup, with an enthusiastic fan base that even has a dedicated Facebook page for the motor.

“The configuration is extremely popular,” says Chris Larson, VP of engineering and quality at the company. He adds that when higher horsepower crate engines started showing up in the market, it was time for BluePrint to respond. “We started working on it about three years ago. It has been reasonable challenge to make 200 more horsepower—going from 815 to 1,015.”

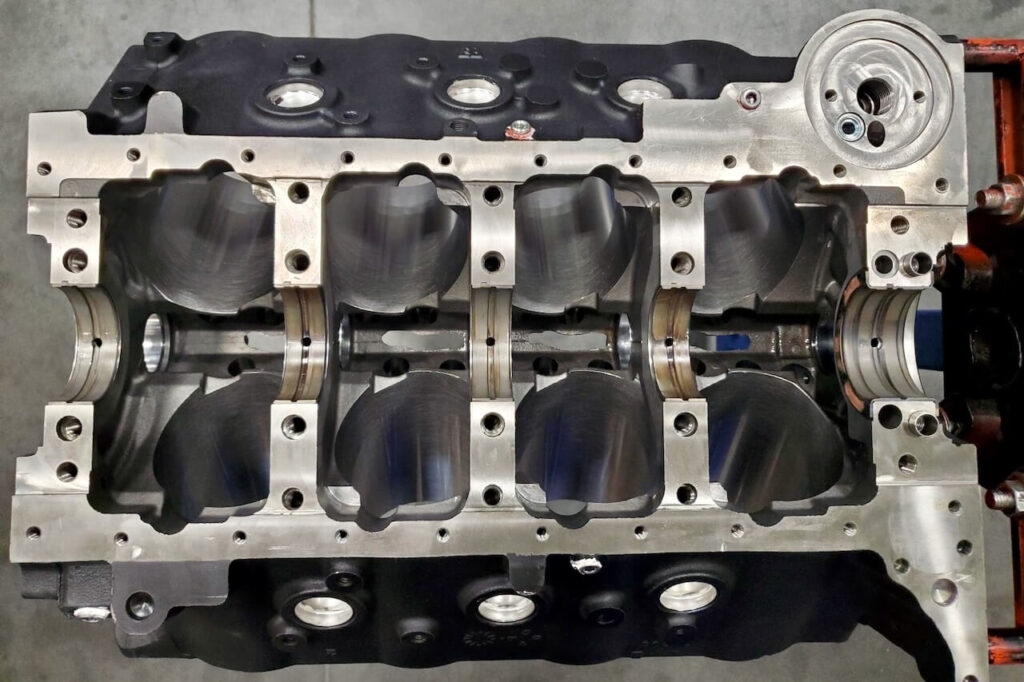

The Callies 8-counterweight crankshaft features a 4.750-inch stroke.

Hints of the engine appeared at SEMA in 2023 with a promise of a full introduction to follow, but issues revealed during durability testing prompted the company to extend the development time and fully validate the components before releasing the engine package to customers.

“Right now, we’re getting production engines going and filling back orders,” says Larson.

During the development, engineers focused on cylinder head, induction and camshaft improvements to make power. But the short block also needed attention to ensure durability.

“We had to make some changes to the bottom end, as well. We upgraded to an eight-counterweight crankshaft (from Callies) to give it better stability at high rpm,” explains Larson. “We also were the first to work closely with Clevite on their new F-series bearing technology for the big-block.

BluePrint worked closely with Mahle to develop the dished-piston design for the 632. Final compression ratio is 10.65:1.

The foundation for the short block is a BluePrint iron cylinder block cast in Germany and machined at BluePrint’s factory in Kearney, Nebraska. It features 4-bolt mains, a 1-piece rear main seal and is bored and finished honed to 4.600-inch. In addition to the Callies 4.750-inch-stroke crankshaft, the short block is also secured with 6.635-inch H-beam connecting rods and Mahle pistons.

“We worked closely with Mahle Motorsports on the pistons. It’s not a common piston. There’s some special sauce that we’ve got going on with rings, clearances and design that makes them really suitable for this application,” says Larson, noting that the compression ratio is 10.65:1. “It was intended to run on pump gas.”

The pistons are installed along with H-beam connecting rods. Note the 4-bolt mains and the double-roller timing set.

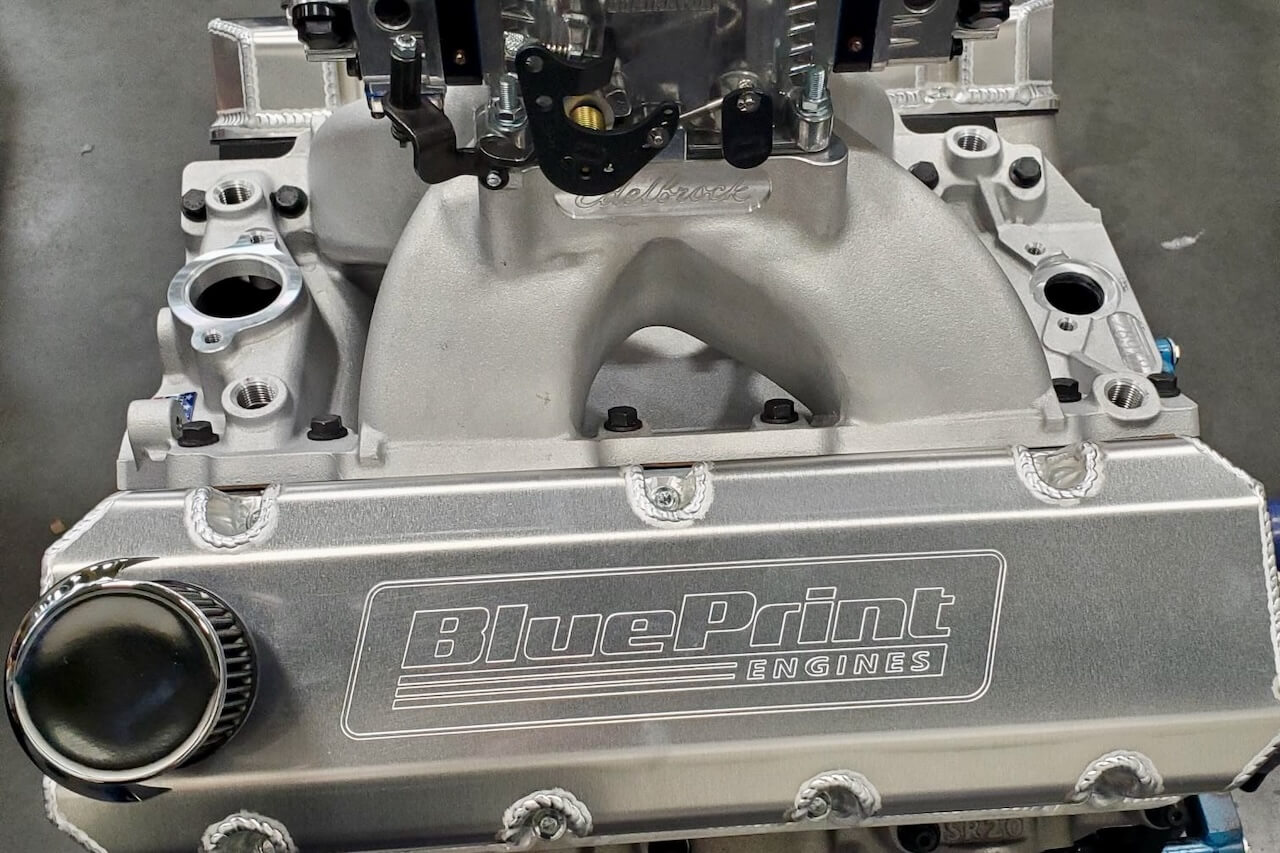

BluePrint tested multiple big-block cylinder heads and settled on the Brodix CNC-machined SR20 heads matched to a Brodix intake manifold. These heads feature a raised 440cc intake port and 2.400-inch intake valve. The exhaust valve measures 1.800-inch. The intake valve angle is 20 degrees with a 4-degree cant, and the exhaust is 13 degree with a 4-degree cant. Combustion chamber volume is 95cc.

“Brodix won on the flow bench and on the dyno,” reports Larson. “There’s some finishing work that we asked them to do for us. It’s a little bit different than what everyone else gets with that head. The BluePrint Engines single-plane intake was up to the task for supporting the target power level.”

Here’s a view of the assembled short block. Note the ARP studs and Morel solid-roller lifters.

The valvetrain was developed working closely with Jesel and Billy Godbold with Godbold Engineering. Jesel shaft-mounted aluminum rockers are mounted to the heads along with Brodix stainless-steel valves and PAC springs. The solid-roller camshaft specs out to 293/304 degrees duration at .050-inch lift on the intake and exhaust sides, respectively. Total valve lift is .873/.861-inch, respectively. Lobe-separation angle is 115 degrees.

Customers have a choice of ordering the engine with a Holley 1,475 cfm 4500-footprint carburetor or the Holley Sniper Stealth 4500 EFI system. The engine also comes with a MSD Pro Billet distributor, spark plugs and wires.

The Brodix SR20 cylinder heads are positioned in place over the MLS head gaskets.

“Both fuel systems performed as expected, but did require calibration, which will be included on production units,” adds Larson.

Jesel developed the shaft rocker arms and stands for the Brodix heads. Other valvetrain components include PAC springs and Brodix stainless-steel valves.

The BluePrint 1,015 crate engine is assembled with MLS head gaskets, ARP head studs, 2000 series rod bolts, upgraded double-roller timing set, SFI-rated damper, BluePrint custom valve covers, Melling oil pump and a Moroso double kick-out oil pan with windage tray.

The heads required a 2-piece spacer to properly mount the intake manifold. Note the BluePrint timing cover.

“We had quite a bit of an issue with windage because this engine turns about 1,500 rpm higher than our standard 632. So, we sourced a special Moroso pan for it. We did not make any changes on the oil pump over the standard 632,” says Larson, adding that BluePrint recommends customers step up to 20W-50 oil instead of the standard 10W-30. “We learned this doing the bearing testing.”

As part of the durability validation, BluePrint subjected the development engine to extensive dyno testing.

BluePrint is using both an Edelbrock and its own single-plane design intake manifold as production ramps up. Bench and dyno testing validated both.

“We’ve got around 600 to 800 dyno passes on the engine,” sums up Larson. “We really treated it like most of our customers who are likely to drag race. So, we spent a lot of time at wide-open throttle just like it would be going down the strip. And then we did sustained durability testing for a week at a time, cycling through a load profile for certain amounts of time for a drivability test. But most of the durability tests designed to break the engine is sustained wide-open testing.”

Each BluePrint engine is dyno tested before being shipped to the customer. This 632ci version is rated at 1,015 horsepower at with 830 lb-ft peak torque.

The 632ci 1,015-horsepower (830 lb-ft peak torque) big-block starts at $21,999 for the carbureted version and sells for $22,999 with the Holley fuel-injection option. The engine comes with a 30-month, 50,000-mile factory warranty when used in an on-highway application.

The BluePrint 632 is finished with BluePrint valve covers, choice of carburetor or EFI induction, MSD distributor and a Moroso oil pan, which was designed with a special kickout feature.